In many manufacturing enterprises, management is mainly focused on product management, quality management, warehouse management, mobile/fixed asset management, production line management, fleet management, etc. Usually, many inbound and outbound storage and inventory information collection is the use of bar codes. However, the pollution/damage of the bar code, the strength of the light, the bar code of the sandwich layer of goods is invisible, and only one to one collection methods, etc., all restrict the efficiency of the bar code collection, which is not conducive to the current situation of the efficient operation of modern intelligent warehousing, and further improve the production capacity.

The use of RFID reading and writing equipment and electronic labels to achieve production line and warehouse management, inventory, but the performance of the selected equipment, antenna and label is in line with the scene, the installation Angle is reasonable and other factors, warehousing inventory operations are standardized, will affect the actual collection results, many users of the input-output ratio can not achieve the desired effect.

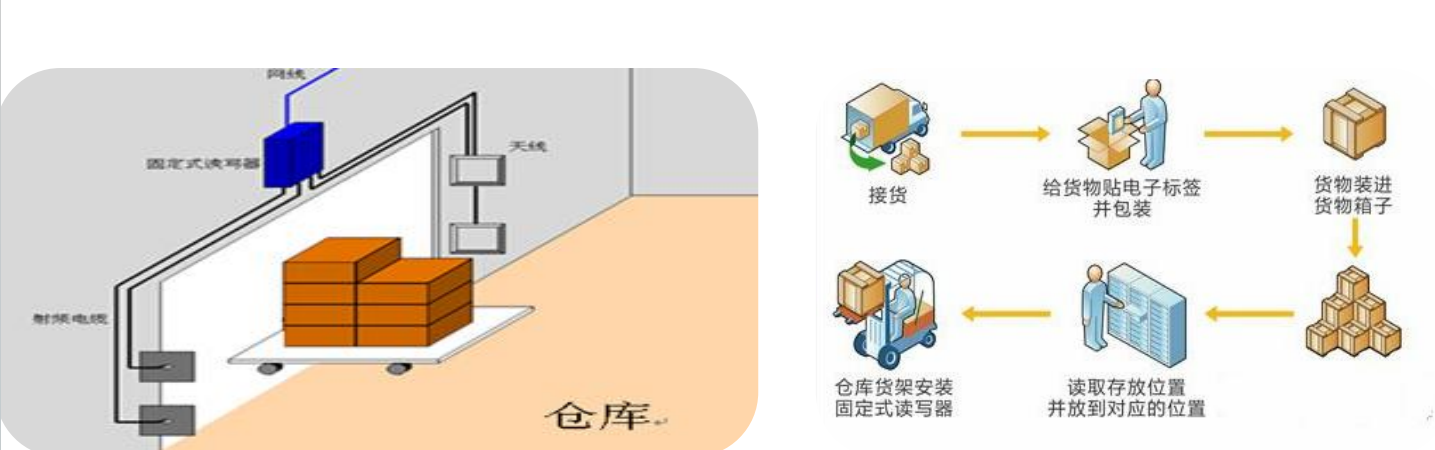

Production, transfer and temporary storage warehouse apply RFID technology, write product information into the label, and bind with the product, and install a reader at the entrance of the warehouse. The system automatically reads the data in the label and the incoming and outgoing action information, shares the data with the business system, and displays the information on the display screen to prompt the warehouse operator how to operate. By combining with ERP, SCM, CRM, MCS and other management systems, RFID allows each employee of the enterprise to play the maximum efficiency. The information collected by the reader is time-stamped, and the information collected by the RFID can be queried and traced through the business management system.