Radio Frequency Identification (RFID) technology, as one of the core technologies of the Internet of Things, has been widely applied in various industries. An RFID system is mainly composed of three parts: a reader-writer, an antenna, and an electronic tag. Among them, as the data carrier, the performance of the electronic tag directly affects the reliability of the entire system. According to the operating frequency, electronic tags can be divided into types such as Low Frequency (LF), High Frequency (HF), Ultra High Frequency (UHF), and Microwave (MW). Moreover, according to the application environment and functional requirements, various specially designed tag products have been derived.

1、 Common types and characteristics of RFID electronic tags

①、UHF Self-adhesive Electronic Tags

Product Features: UHF self-adhesive electronic tags are made of flexible base materials and have a strong adhesive layer on the back, which can be directly pasted on the surface of various items. These tags usually operate at a frequency between 860-960MHz and have the following characteristics: long reading distance (up to more than 10 meters), small, compact, thin and light in size, relatively low cost, and the ability to print corporate logos or barcode information.

Typical Application Scenarios:

① Retail Management: Single-item level management of clothing, shoes and hats, electronic products, etc.

② Logistics and Warehousing: Identification of logistics units such as cartons and pallets

③ Document Management: Tracking of important files, contracts and other documents

④ Asset Management: Management of non-metallic items such as office equipment and instruments

Ultra high frequency adhesive electronic label

②、Flexible Anti-metal Electronic Tags

Product Features: Flexible anti-metal electronic tags use specially designed anti-metal materials as the base, which can effectively solve the problem of the sharp decline in the performance of ordinary tags on metal surfaces. They are optimized for design on metal surfaces and maintain the flexible and bendable characteristics. The thickness is usually between 1-3mm, and they have excellent high-temperature resistance and corrosion resistance.

Typical Application Scenarios:

① Management of Metal Containers: Chemical barrels, gas cylinders, etc.

② Equipment Asset Management: Instruments and equipment with metal casings

③ Management of Automobile Parts: Engine parts, gearboxes, etc.

④ Management of Power Equipment: Transformers, power distribution cabinets, etc.

Flexible anti metal electronic tag

③、PCB Anti-metal Electronic Tags

Product Features: PCB anti-metal electronic tags use Printed Circuit Board (PCB) as the base material, featuring excellent anti-metal performance and stability. With a rigid structure, they have high mechanical strength and strong environmental adaptability (-40°C to 85°C). Their reading performance is stable and reliable, and different sizes and shapes can be customized.

Typical Application Scenarios:

① Industrial Equipment Management: Machine tools, production line equipment

② Electric Power and Telecommunications: Base station equipment, power facilities

③ Military Equipment: Weapon systems, logistics equipment

④ Outdoor Assets: Transportation facilities, municipal equipmen

PCB anti metal electronic tag

④、ABS Anti-metal Electronic Tags

Product Features: ABS anti-metal electronic tags are encapsulated with an ABS engineering plastic shell, combining both anti-metal performance and protection performance. The waterproof and dustproof level can reach up to IP67. They are resistant to impact and vibration, making them suitable for harsh industrial environments. There are various installation methods available, such as screw fixation and pasting.

Typical Application Scenarios:

① Construction Machinery Management: Excavators, cranes, etc.

② Container Management: Marine and railway containers

③ Oil and Gas Industry: Facilities such as pipelines and valves

④ Outdoor Asset Management: Traffic signs, street lamps, etc.

ABS anti metal electronic tag

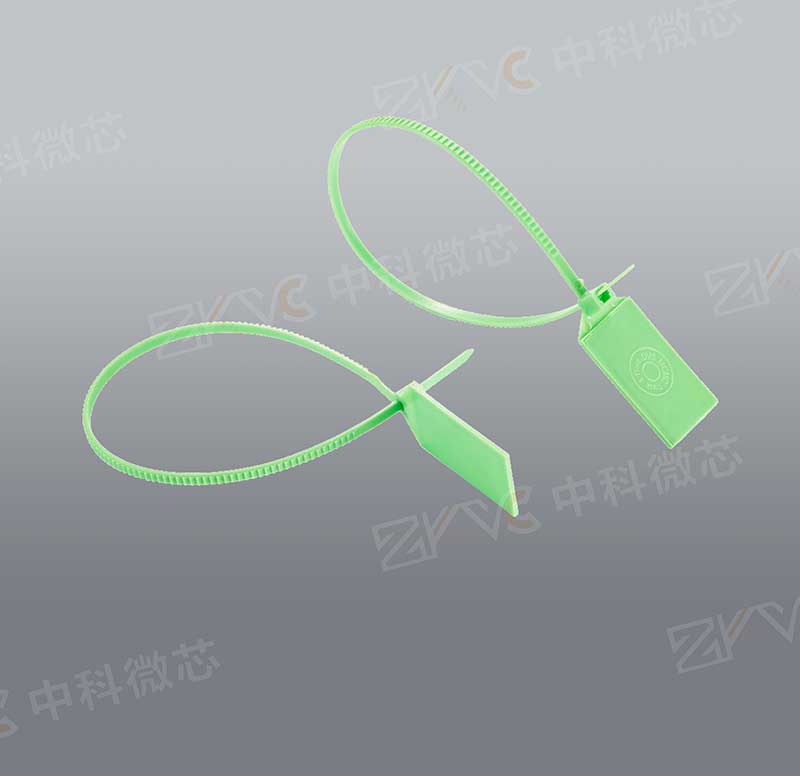

⑤、UHF Cable Tie Electronic Tags

Product Features: UHF cable tie electronic tags ingeniously combine the RFID chip with the cable tie structure to achieve the functions of one-time fixation and identification. They are easy to install, can be fixed in a one-time manner, and feature an anti-disassembly design, which improves security. They are suitable for cylindrical objects, have strong weather resistance, and have a long outdoor service life.

Typical Application Scenarios:

① Power Inspection: Identification of cables and electricity meters

② Gas Management: Management of pipelines and gas meters

③ Forestry Management: Identification and tracking of trees

④ Animal Management: An alternative solution for livestock ear tags

Ultra high frequency cable tie electronic tag

2、Development Trends of RFID Technology

With the development of Internet of Things (IoT) technology, RFID electronic tags exhibit the following trends:

Miniaturization: Tags with smaller sizes can meet the needs of more application scenarios.

Intelligence: By integrating sensors, they can achieve environmental monitoring such as temperature and humidity.

Low Cost: The large-scale application promotes the continuous decline of tag costs.

Environmental Friendliness: The application of degradable materials helps to reduce electronic waste.

Multi-functional Integration: They are integrated with technologies such as two-dimensional codes and NFC.

3、Conclusion on RFID Electronic Tags

As a bridge between the physical world and the digital world, RFID electronic tags with their diversified designs meet the identification needs of different industries and environments. From ultra-high frequency self-adhesive tags to various anti-metal tags, and then to special cable tie tags, the rich product line provides a solid foundation for the digital transformation of various industries. With the continuous innovation of technology and the continuous expansion of application scenarios, RFID technology will play a more important role in the era of the Internet of Things, driving the development of various industries towards intelligence and high efficiency. When choosing RFID tags, enterprises need to consider factors such as the application environment, reading distance, installation method, and cost budget, and select the solution that best suits their own business needs.